We’ve got three King Kegs in the Cheshire Peaks cellar (OK, garage). Back in 2012 I bought a pressure gauge for one of them off eBay. You can read the post about it and the quest to make lager fizzy.

But the other two kegs remained without gauges. This has proved to be a complete pain. Here’s why.

When we serve beer through the beer engine, it is necessary to put some gas into the top of the keg to prevent building up a vacuum that eventually stops the beer coming out, or worse sucks air back into the keg through the tap. In a British pub cellar the gas going into the top of a cask is air (in other words there is a hole in the top of the cask). This keeps the pressure in the cask at exactly ambient pressure but also means the beer stales in a few days.

The solution at home is to inject carbon dioxide to fill the head space rather than allow air in. This keeps the beer fresh for many weeks. But without a pressure gauge it is always guesswork as to whether the keg needs gas adding or not. If you get it wrong you build up a vacuum and end up sucking air back into the keg through the tap next time you try to draw some beer. Bad.

The other problem I have encountered is that especially during the summer there will still be a little yeast activity in the keg which gradually builds up pressure in the keg. This is OK as long as it does not get too high. But I have had one or two incidents where the pressure in the keg built up too high and I was not aware of it. Fortunately I never had a catastrophic failure like a split barrel. What King Kegs tend to do instead is seep round the hole where the tap screws into the keg. Eventually I was discovering a beery smell in the garage and the keg sat in a sticky pool of beer.

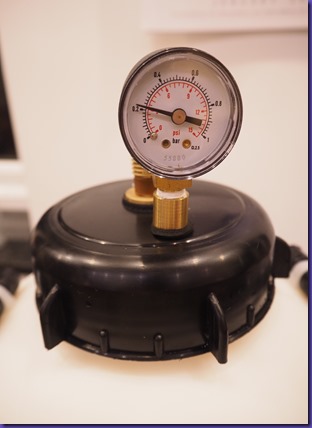

So more pressure gauges had to be procured. Last time I bought a ready made kit - a pressure gauge and the necessary washer, nut and rubber seal all ready to fit to a King Keg. It took me several months to see a similar kit appear again on eBay, so when it did I grabbed two. (Sold by rocnsoc1969 if you want to see if they have any more on offer). They were £18 each.

Fitting is simply a case of carefully drilling a 10mm hole in the soft plastic of the keg lid. I started with a pilot hole, then expanded it to 9.5mm because that allowed me to screw the threaded shaft snugly into the plastic and it “self tapped” into the plastic.

I had to be accurate with the positioning of the hole so it was not too close to the S30 valve in the middle of the lid – it needs clearance for the CO2 bottle to be able screw down without hitting the pressure gauge (see second to last photo). But it must also not be so far out that the brass washer inside the lid hits the channel in which the rubber seal sits – see the photo above.

No comments:

Post a Comment